U Slot End Mill tsis muaj Caoting rau Aluminium

D1*3*D4*50L

D1.5*4.5*D4*50L

D2*6*D4*50L

D2.5*7.5*D4*50L

D3*9*D4*50L

Spotlight Exhibits

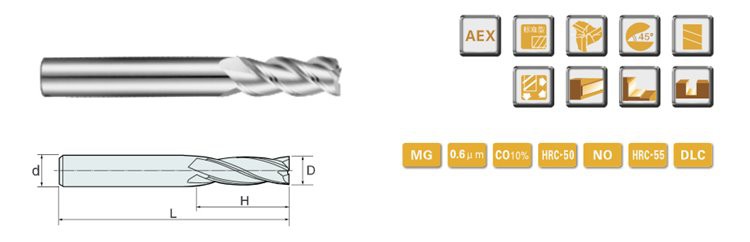

Kev piav qhia

Hauv kev ua haujlwm ntawm precision machining, cov cuab yeej zoo tuaj yeem ua lub luag haujlwm tseem ceeb, ib yam li qhov no U Slot End Mill tsis muaj Caoting rau Aluminium. Nws yog tshwj xeeb tsim los rau kev ua txhuas, thiab nws yog cov cuab yeej tshwj xeeb txiav, txhawm rau ua kom raug thiab ua tau zoo tuav cov haujlwm ua txhuas. Lub cutter txais cov qauv cemented carbide, tau ua tib zoo tsim, muaj tshwj xeeb U-puab me ntsis thiab hnav-resistant yam ntxwv, thiab tau ua tau zoo nyob rau hauv ntau yam milling daim ntaub ntawv. Txawm hais tias koj nyob hauv lub tsheb, aerospace lossis kev lag luam machining, qhov cuab yeej no yog thawj qhov kev xaiv rau koj kom tshem tawm cov ntaub ntawv zoo, ua tiav lub ntsej muag du thiab ua kom qhov tseeb ntawm txhua qhov kev txiav.

Nta

1. Kev ua haujlwm zoo: Qhov no U Slot End Mill tsis muaj Caoting rau Aluminium yog ib qho tseem ceeb ntawm kev tshem tawm cov khoom hnyav nyob rau hauv ib lub sij hawm, muab kev txhim kho ntug smoothness rau saum thiab hauv qab ntawm lub workpiece, thiab txo qhov kev xav tau ntawm cov txheej txheem ntxiv.

2. Integral qauv: Qhov kawg zeb no yog ua los ntawm cov khoom siv zoo cemented carbide, uas muaj hardness zoo, durability thiab hnav.

tsis kam. Txawm tias nyob rau hauv hnyav machining tej yam kev mob, nws yuav tsis yooj yim deformed los yog tawg, uas yuav ua tau kom lub neej ntev kev pab cuam ntawm lub cuab tam.

3. Multi-directional txiav hniav: Nws lub cev nto thiab txiav ntug yog skillfully tsim nrog txiav hniav, uas muaj peev xwm txiav ntau yam ntaub ntawv nyob rau hauv ntau yam lus qhia, ua rau nws yog ib qho zoo tagnrho cov cuab yeej rau kev ua hauj lwm ntau yam.

4. Groove tsim: nws U-groove tsim yog lub hauv paus ntawm kev ua tau zoo thiab cov nyhuv ntawm cov cuab yeej. Lub concave laum simplifies thiab accelerates tus txheej txheem txiav, realizing du txiav yam tsis muaj lwm yam polishing.

Daim ntawv thov

-

Aluminium ua: Cov khoom no ci ntsa iab nyob rau hauv daim ntawv thov ntawm txhuas ua. Nws tuaj yeem tshem tawm cov ntaub ntawv hnyav ib zaug, thiab nws qhov chaw du ua rau nws yog ib qho tseem ceeb rau kev tsim cov khoom txhuas.

-

Kev lag luam tsheb: Hauv kev lag luam tsheb, lub milling cutter plays lub luag haujlwm tseem ceeb hauv kev tsim cov khoom siv txhuas xws li cav qhov chaw, chassis qhov chaw thiab lub cev vaj huam sib luag.

-

General machining: Ntxiv nrog rau kev lag luam kev lag luam, nws kuj yog siv rau kev siv machining dav dav uas yuav tsum tau ua kom du nto thiab tshem tawm cov khoom zoo.

Hoobkas

Product Description

|

SPECIFICATION |

d1 |

L1 |

D |

L |

|

D1*3*D4*50L |

1 hli |

3mm ib |

4mm ib |

50 hli |

|

D1.5*4.5*D4*50L |

1.5 hli |

4.5mm ib |

4mm ib |

50 hli |

|

D2*6*D4*50L |

2 hli |

6mm ib |

4mm ib |

50 hli |

|

D2.5*7.5*D4*50L |

2.5 hli |

7.5mm ib |

4mm ib |

50 hli |

|

D3*9*D4*50L |

3mm ib |

9mm ib |

4mm ib |

50 hli |

|

D3.5*10*D4*50L |

3.5mm ib |

10 hli |

4mm ib |

50 hli |

|

D4*12*D4*50L |

4mm ib |

12 hli |

4mm ib |

50 hli |

|

D4*16*D4*75L |

4mm ib |

16 hli |

4mm ib |

75mm ua |

|

D4*20*D4*100L |

4mm ib |

20 hli |

4mm ib |

100 hli |

|

D5*15*D5*50L |

5mm ua |

15 hli |

5mm ua |

50 hli |

|

D5*20*D5*75L |

5mm ua |

20 hli |

5mm ua |

75mm ua |

|

D5*25*D5*100L |

5mm ua |

25 hli |

5mm ua |

100 hli |

|

D6*18*D6*50L |

6mm ib |

18 hli |

6mm ib |

50 hli |

|

D6*24*D6*75L |

6mm ib |

24mm ib |

6mm ib |

75mm ua |

|

D6*30*D6*100L |

6mm ib |

30 hli |

6mm ib |

100 hli |

|

D8*24*D8*60L |

8mm ib |

24mm ib |

8mm ib |

60 hli |

|

D8*30*D8*75L |

8mm ib |

30 hli |

8mm ib |

75mm ua |

|

D8*35*D8*100L |

8mm ib |

35mm ib |

8mm ib |

100 hli |

|

D10*30*D10*75L |

10 hli |

30 hli |

10 hli |

75mm ua |

|

D10*45*D10*100L |

10 hli |

45mm ib |

10 hli |

100 hli |

|

D12*35*D12*75L |

12 hli |

35mm ib |

12 hli |

75mm ua |

|

D12*45*D12*100L |

12 hli |

45mm ib |

12 hli |

100 hli |

|

D14*45*D14*100L |

14mm ib |

45mm ib |

14mm ib |

100 hli |

|

D16*45*D16*100L |

16 hli |

45mm ib |

16 hli |

100 hli |

|

D18*45*D18*100L |

18 hli |

45mm ib |

18 hli |

100 hli |

|

D20*45*D20*100L |

20 hli |

45mm ib |

20 hli |

100 hli |

|

D6*45*D6*150L |

6mm ib |

45mm ib |

6mm ib |

150 hli |

|

D8*50*D8*150L |

8mm ib |

50 hli |

8mm ib |

150 hli |

|

D10*60*D10*150L |

10 hli |

60 hli |

10 hli |

150 hli |

|

D12*60*D12*150L |

12 hli |

60 hli |

12 hli |

150 hli |

|

D14*70*D14*150L |

14mm ib |

70 hli |

14mm ib |

150 hli |

|

D16*75*D16*150L |

16 hli |

75mm ua |

16 hli |

150 hli |

|

D18*75*D18*150L |

18 hli |

75mm ua |

18 hli |

150 hli |

|

D20*75*D20*150L |

20 hli |

75mm ua |

20 hli |

150 hli |

|

Tolerances |

||

|

Flute Diameter |

Flute Diameter Tolerance |

Shank Diameter kam rau ua |

|

Φ1.0-Φ2.9 |

0--0.02 |

H6 |

|

Φ3-Φ6 |

-0.01--0.03 |

|

|

Φ6-Φ10 |

-0.01--0.035 |

|

|

Φ10.0-Φ18.0 |

-0.01--0.04 |

|

|

Φ18.0-Φ20.0 |

-0.015--0.045 |

|

|

Daim ntawv thov |

||||||||

|

Carbon Steel |

Pre-harden steel |

High-hardened |

Stainless hlau |

Tooj Alloy |

Aluminium Alloy |

|||

|

45 HRC |

50 HRC |

55 HRC |

60 HRC |

65 HRC |

||||

|

|

|

|

|

|

|

|

|

○ |

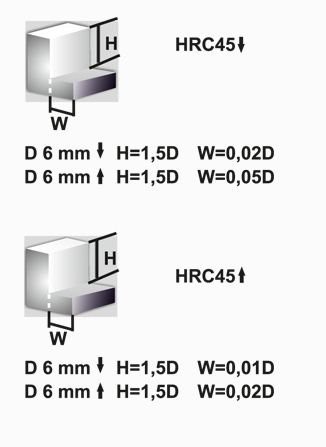

Pom zoo Parameters

|

Khoom siv |

Carbon Steel, Alloy Steel, S45C, FC, FCD, SCM, S50C, SKS ... |

Alloy Steel, Tool Steel SCR, SNCM, SKD11, SKD61.NAK80 |

Hard Steel, SKD11 |

|||

|

Hardness |

HRC 30 |

HRC 50 |

HRC 60 |

|||

|

Txoj kab uas hla |

Txiav ceev (VC) (mm{0}}) |

Pub (F) (mm-min) |

Txiav ceev (VC) (mm{0}}) |

Pub (F) (mm-min) |

Txiav ceev (VC) (mm{0}}) |

Pub (F) (mm-min) |

|

1 hli |

22000 |

400 |

18000 |

200 |

9000 |

140 |

|

1.5 hli |

12000 |

500 |

11000 |

280 |

5200 |

150 |

|

2 hli |

10000 |

550 |

10000 |

280 |

4600 |

170 |

|

3mm ib |

9000 |

600 |

5500 |

310 |

3500 |

220 |

|

4mm ib |

6000 |

750 |

5000 |

400 |

2200 |

220 |

|

5mm ua |

4800 |

800 |

4000 |

400 |

1700 |

240 |

|

6mm ib |

4500 |

820 |

3800 |

420 |

1600 |

300 |

|

8mm ib |

3500 |

820 |

2800 |

420 |

1000 |

300 |

|

10 hli |

3000 |

820 |

1800 |

420 |

900 |

300 |

|

12 hli |

2000 |

820 |

1600 |

350 |

800 |

300 |

|

16 hli |

1500 |

650 |

1000 |

300 |

500 |

150 |

|

20 hli |

1200 |

650 |

900 |

300 |

400 |

150 |

|

|

Raw Material List

|

Qib |

ISO Code |

Chemical Compositions (%) |

Grain Size (um) |

Physial Mechanical Properites (Ntau dua lossis sib npaug) |

Txheej |

|||

|

Wc |

Co |

Qhov ceev (g / cm3) |

Hardness (HRA) |

TRS (N / hli 2) |

||||

|

YG10X (50HRC) |

K30-K40 |

89 |

10 |

0.8 |

14.43 |

91.5 |

2500 |

TSI |

|

UF12U (55HRC) |

K40 |

87 |

12 |

0.6 |

14.15 |

92.3 |

3900 |

TSI |

|

AF501 (60HRC) |

K05-K10 |

89 |

10 |

0.4 |

14.1 |

92.8 |

3600 |

NANO BLACK |

|

AF308 (65 HRC) |

K05-K10 |

91 |

8 |

0.3 |

14 |

93.8 |

3800 |

NANO (xim xiav) |

Cov duab ntxaws

| U qhov kawg zeb tsis muaj caoting rau Aluminium | U slot cutter tsis muaj caoting rau Aluminium | U qhov milling cutter tsis muaj caoting rau Aluminium |

|

|

|

Peb Qhov Zoo

1) High precision CNC tshuab, siab tus qauv thiab nruj soj ntsuam

2) Kev thov kev cai yog txais tos, OEM thiab ODM Service

3) Tag nrho cov nqe lus them nqi txhawb nqa

4) Lub sijhawm xa khoom sai thiab kev thauj mus los yooj yim

Ntim

FAQ

1.Koj tus MOQ yog dab tsi? Kuv puas tuaj yeem sib xyaw cov qauv sib txawv rau qhov kev txiav txim pib?

A: Thov qhia peb yam khoom koj xav tau ua ntej. Zoo li compression fittings, MOQ yog 100pcs.Tab sis peb tuaj yeem muab cov khoom lag luam ua qauv rau koj los xyuas qhov zoo ua ntej.

2.Koj puas tuaj yeem muab luv nqi rau kuv?

A: Kev txo nqi yog muaj, tab sis peb yuav tsum pom qhov muaj nuj nqis tiag tiag, peb muaj tus nqi sib txawv raws li qhov sib txawv, qhov kev txo nqi ntau npaum li cas yog txiav txim siab los ntawm qhov ntau, ntxiv rau, peb cov nqi sib tw heev hauv kev lag luam.

3.Yog tias kuv muaj cov khoom xav tau los ua lwm yam khoom tshwj xeeb, koj puas tuaj yeem ua nws?

A: Tau kawg, koj tsuas yog xav muab peb cov duab kos lossis qauv thiab R & D department yuav kwv yees seb peb tuaj yeem ua tau lossis tsis ua, peb yuav muab cov lus teb txaus siab tshaj plaws rau koj.

Cim npe nrov: u qhov kawg zeb tsis muaj caoting rau txhuas, Tuam Tshoj u qhov kawg zeb tsis caoting rau txhuas manufacturers, lwm tus neeg, Hoobkas

Koj Tseem Yuav Zoo Li

Xa kev nug